When it comes to damaged or broken pipes, replacement has traditionally been the go-to solution, but we all know it comes with a hefty price tag, major disruption, and a timeline that can feel endless. Digging up your yard, breaking through concrete floors, and dealing with a construction mess is stressful and costly, but sometimes it’s absolutely necessary.

Fortunately, there’s a smarter alternative: pipe relining. This innovative plumbing solution repairs your pipes from the inside out, using just a small access point (often as little as one square metre!) so there’s no need to rip up your garden or tear through your floors. Not only does it save time, but it also costs less and delivers results that often outperform traditional repairs.

In this post, we’ll explore what pipe relining is, how the process works, the types of problems it can solve, and why it’s quickly becoming the preferred choice for homeowners and businesses looking for a fast, effective, and minimally disruptive way to fix their pipes.

Key Takeaways:

- No-Dig, No Mess: Pipe relining fixes your damaged pipes from the inside, so there’s no need to tear up your yard, driveway, or floors.

- Quick and Easy: Most jobs are done in a single day, and you can start using your plumbing right away.

- Built to Last: The tough, resin-coated liner creates a “pipe within a pipe” that’s corrosion-resistant and can last 25–50 years.

- Works on All Pipes: PVC, metal, clay, concrete, fibreglass, composite, or earthenware, relining handles them all.

- Solves Everyday Problems: Say goodbye to recurring blockages, tree root damage, leaks, and nasty odours.

- Saves You Money: Usually cheaper than a full pipe replacement, without the costs of digging or repairing your property.

- Environmentally friendly: Less waste, non-toxic materials, and lower energy use make relining an eco-friendly choice.

Understanding Pipe Relining

Pipe relining is a modern, trenchless plumbing solution that fixes damaged pipes without the need to dig them up. Instead of tearing apart your yard, breaking through concrete, or dismantling structures, this method repairs pipes from the inside out using existing access points. This means less mess, less disruption, and a much lower overall cost compared to traditional replacement.

But how does it actually work? By creating a new pipe inside your old one.

A flexible textile liner, often made of polyester or fibreglass, is custom-fitted to the pipe’s exact size and shape. This liner is coated in epoxy resin and inserted into the damaged pipe using air or water pressure. Once inflated, the liner presses snugly against the interior walls of the pipe.

The resin is hardened and forms a tough, corrosion-resistant “pipe within a pipe.” Suitable for pipes ranging from 0.1 to 2.8 metres wide, pipe relining is highly versatile and effective across residential, commercial, and industrial plumbing systems.

Pipe relining works on a wide variety of materials, including:

- PVC Pipes

- Metal Pipes

- Clay Pipes

- Concrete Pipes

- Fibreglass, composite, and even earthenware pipes.

Common Pipe Problems That Lead to Relining

Recurring Blockages and Slow Drainage

If your sinks, showers, or toilets drain slowly, or you keep facing blocked drains even after regular cleaning, it’s usually a sign of a deeper issue. Tree roots, debris buildup, or damaged pipes can obstruct water flow, and standard drain cleaning often only provides a temporary fix. When blockages keep coming back within weeks, it’s a strong indicator that your pipes have structural problems rather than simple clogs.

Tree Root Intrusion and Cracked Pipes

Trees are always on the lookout for water, and unfortunately, your plumbing pipes make an irresistible target. Roots can squeeze through leaky joints, broken seals, or worn-out sections of pipe. Once inside, they continue to grow, obstructing water flow and putting pressure on the pipes. Over time, this pressure can crack, collapse, or displace your pipes entirely, causing serious damage if left untreated.

Water Leaks and Foul Odours

Broken pipes don’t just affect water flow; they can also cause leaks, leaving damp patches, water stains, or puddles around your property too. Sewage leaks are even more concerning, as they can introduce harmful bacteria into your home and create persistent, unpleasant odours. These smells often result from sewer gas escaping through damaged pipes or trapped sewage. Beyond being unpleasant, water leaks and sewer issues can compromise your property’s structure and pose health risks.

Pre-Sale Plumbing Upgrades

Pipe relining is also a smart way to upgrade ageing plumbing systems without the cost and disruption of a full replacement. By strengthening and modernising existing pipes from the inside, relining improves performance, reduces the risk of leaks, and extends the lifespan of your plumbing.

For homeowners preparing to sell, this upgrade can be especially beneficial. Buyers and inspectors pay close attention to plumbing, looking for signs of leaks, water pressure issues, and overall efficiency. Relining ensures your plumbing system is in top shape, giving buyers peace of mind and helping you secure a smoother, more profitable sale.

Benefits of Pipe Relining Over Traditional Replacement

Pipe relining has quickly become the smarter choice when it comes to pipe repair and replacement, and it’s easy to see why! Here’s why more property owners are making the switch:

No Digging or Excavation Required

Traditional replacement often means tearing up lawns, gardens, driveways, and even building foundations with extensive trenching. Relining, on the other hand, uses just a small access point, sometimes as little as one square metre, or existing manholes and structures. This no-dig approach protects your landscaping and saves thousands in restoration costs.

Faster Turnaround Time (Often Same-Day)

Relining dramatically reduces downtime. Most projects are completed in a single day, and even long stretches of pipe (100+ metres) can be restored quickly. Better still, your plumbing is usually ready to use almost immediately after installation. By contrast, traditional replacement can leave you without working pipes for days or even weeks for extensive projects.

Improved Water Flow and Pipe Strength

While relining makes pipes slightly narrower, the smooth, resin-coated surface actually improves water flow, boosting it by as much as 25–50%. The hardened liner is stronger than many original pipe materials and offers superior resistance against cracks, corrosion, and tree root intrusion.

Minimal Disruption to Property and Routine

Because there’s no excavation, your property stays intact. Gardens, driveways, floors, and structures remain untouched, which means your daily life or business operations can continue with almost no interruption. For businesses, this can mean avoiding costly downtime and lost revenue.

Environmentally Friendly Solution

Relining also benefits the environment. It creates far less waste than traditional replacement, uses non-toxic materials, and reduces the need for heavy machinery. With less energy use and fewer carbon emissions, it’s a greener choice for modern plumbing.

Step-by-Step Pipe Relining Process Explained

Pipe relining might sound complex, but the process is relatively straightforward when handled by professionals. Here’s a clear breakdown of how it works:

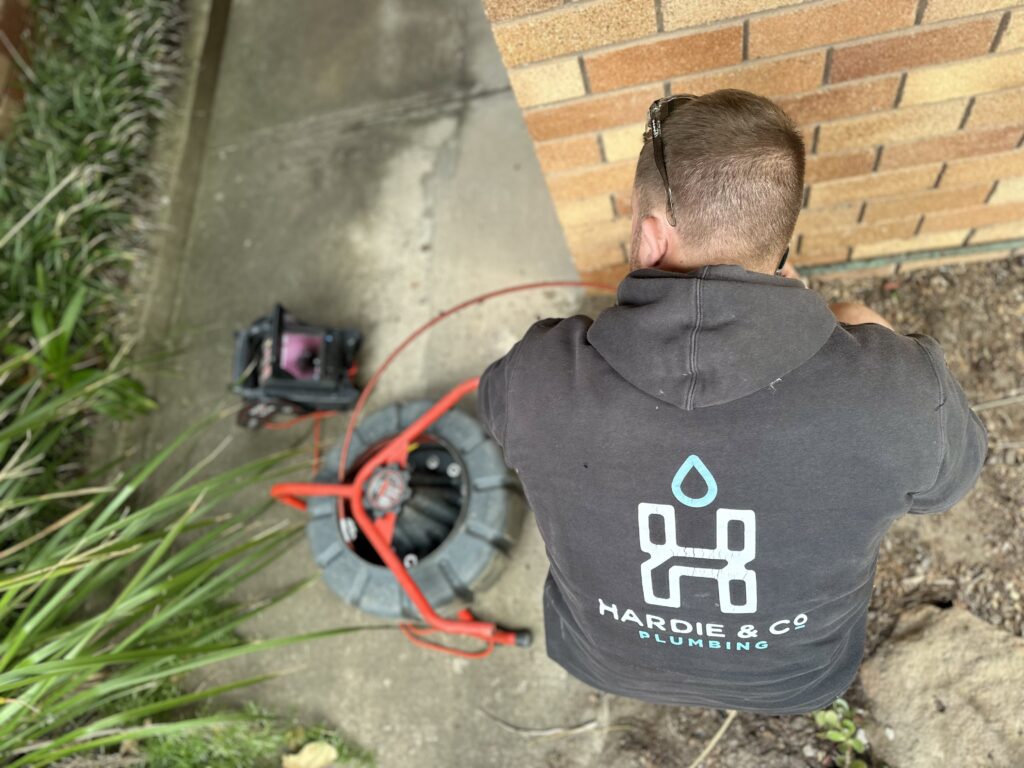

1. CCTV Inspection of Damaged Pipes

The first step is a thorough diagnostic inspection. Technicians insert a high-definition CCTV camera through access points like manholes to travel inside your pipes. This live footage reveals cracks, leaks, blockages, tree root intrusions, and other defects in real time.

The inspection not only confirms whether relining is the best solution but also helps create a precise plan of action. A detailed report, complete with annotated images and videos, documents the pipe’s condition.

2. Pipe Cleaning Using Hydro-Jetting

Once relining is confirmed, the pipes must be cleared of any obstructions. High-pressure water jetting blasts away debris, grease, scale, and invasive roots from the pipe walls. This deep clean ensures the liner and resin will bond securely. For older or fragile pipes, technicians carefully adjust the pressure to prevent damage while still achieving a smooth, clean surface.

3. Resin Preparation and Liner Insertion

Next comes the preparation of the liner. Technicians cut it to the exact length required, then saturate it with a two-part epoxy resin mixed with a hardening agent. The liner is rolled multiple times to ensure even absorption before being carefully inserted into the pipe. Depending on the situation, insertion is done using inversion (air or water pressure pushes the liner into place) or a pull-in-place technique.

4. Curing the Liner with Heat or UV Light

Once in position, the liner needs to harden, or “cure.” Several curing methods are available:

- Hot Water Curing: Heated water circulates inside the liner, ideal for larger pipes or long runs.

- Steam Curing: Uses hot steam for faster results with moderate temperatures.

- UV Light Curing: The fastest option, using ultraviolet light to harden resin infused with photoinitiators.

Depending on the method and pipe length, curing takes just a few hours to a day. Once hardened, the resin forms a seamless, durable new pipe inside the old one.

5. Final Inspection and Junction Reopening

After curing, a second CCTV inspection ensures the liner has bonded perfectly and that the new pipe is smooth, watertight, and fully functional. For pipes with side connections, robotic cutters reopen the junctions with precision. Some businesses will offer a detailed before-and-after report to confirm the relining was successful and your pipes are ready to use.

Limitations and When Pipe Relining May Not Work

Yes, pipe relining is fast, durable and non-invasive, but like any solutions, it has its limits. Understanding when relining may not be suitable helps you make informed decisions about the best approach for your plumbing.

Severely Collapsed or Misaligned Pipes

For relining to work, the existing pipe must have enough structural integrity to support the liner. If a pipe has completely collapsed, shifted too far out of alignment, or is badly crushed, there’s nothing stable for the liner to bond to. In these cases, a CCTV inspection will reveal that traditional excavation and full pipe replacement are the only effective options.

Large Gaps or Missing Pipe Sections

Relining requires an existing “host pipe” for the resin-soaked liner to attach to. If large chunks of the pipe are missing or if significant gaps have formed due to corrosion or deterioration, the liner can’t form a reliable structure.

This issue is often seen in older cast iron pipes in coastal areas where saltwater corrosion has eaten away the material. In such cases, spot excavation or partial replacement may be needed before relining can proceed.

Cost Comparison: Relining vs Replacement

When weighing up pipe relining against traditional replacement, cost is often one of the biggest deciding factors. Both solutions vary depending on the job, but relining typically offers better value when you factor in time, disruption, and long-term durability.

Pipe Relining Costs

In Australia, pipe relining usually costs $400 to $1,000 per metre for clay pipes. For a standard residential job, homeowners generally spend between $3,000 and $15,000. While more complex projects, like those involving deeper or obstructed pipes, may cost more, relining comes with major advantages: it’s quicker, cleaner, and often backed by extensive guarantees.

Pipe Replacement Costs

Traditional replacement is often far more expensive due to the excavation work involved. On average, you can expect to pay $1,000 to $5,000 or more per metre. These costs include not just the new pipe itself, but also excavation, labour, permits, inspections, fittings, and property restoration. For pipes buried under driveways, landscaped gardens, or concrete slabs, costs can skyrocket.

Factors That Affect Pricing

Whether you choose relining or replacement, several factors influence the final price:

- Pipe material and diameter: clay, cast iron, or PVC, each varies in cost

- Length of pipe: longer damaged sections cost more

- Access and complexity: pipes under concrete or in tricky locations add labour and time

- Property type: residential and commercial projects are typically priced differently

- Location: rates vary between Australian cities and regions

The Smarter, Cleaner Alternative to Traditional Pipe Replacement

Pipe relining has changed the way property owners address damaged pipes. It offers a faster, cleaner, and more cost-effective solution for many homes and businesses. By creating a strong, seamless new pipe inside the old one, this trenchless method fixes common problems like blockages, leaks, and tree root intrusion.

For Sydney property owners looking for efficient, low-impact pipe repairs, Hardie & Co Plumbing provides expert trenchless pipe relining. Get your pipes restored without the mess. Contact us today for a quote and see why pipe relining is the future of plumbing maintenance.